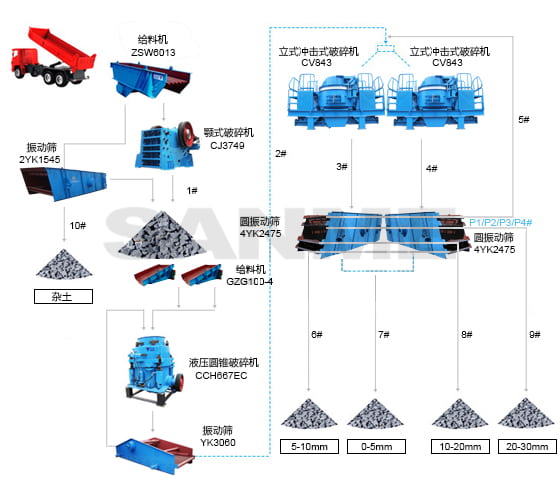

500 TONS OF GRANITE BASALT SAND PRODUCTION LINE

DESIGN OUTPUT

500TPH

MATERIAL

Granite, basalt, pebble

APPLICATION

Cement concrete, asphalt concrete and all kinds of stable soil materials in construction projects, as well as roads, Bridges, culverts, tunnels, lighting and highway projects.

EQUIPMENTS

Cone crusher,VSI sand making machine, sand washing machine,YK series round vibrating screen, belt conveyor

The basic flow

There are many basalt resources in China, which vary from place to place. Therefore, when configuring the equipment, the wear resistance of the solution should be placed in the main position. Take basalt below 200mm as an example: the material is transported to 1# vibrating screen in the raw material bin through the feeder and belt conveyor for pre-screening, the material larger than 40mm is crushed into the conical fracture, 5-40mm into the vertical impact crusher for crushing, 0-5mm into the sand washing machine for cleaning and then directly out the finished product. After the cone is broken, the product is screened by 2# vibrating screen. Those larger than 40mm return the cone to be broken again, forming a closed-circuit cycle, while those smaller than 40mm enter the vertical impact breaking. The material from the vertical impact fracture is screened by 3# vibrating screen, and the material larger than 20mm is returned to the vertical impact fracture for crushing, forming a closed circuit cycle. The material less than 20mm is transported to the finished material pile through the belt conveyor. According to the cleanliness of the raw material, the 0-5mm material can be sent to the sand washing machine for cleaning.

|

serial number

|

name

|

type

|

power(kw)

|

number

|

|

1

|

Vibrating feeder

|

ZSW6013

|

22

|

1

|

|

2

|

jaw crusher |

CJ3749

|

160

|

1

|

|

3

|

Hanging feeder

|

GZG100-4

|

2x2X1.1

|

2

|

|

4

|

Hydraulic cone break

|

CHH667EC

|

280

|

1

|

|

5

|

Vibrating screen

|

YK3060

|

30

|

1

|

|

6

|

Vertical impact fracture

|

CV843

|

2x2x220

|

2

|

|

7

|

Vibrating screen

|

4YK2475

|

2x45

|

2

|

|

8

|

Vibrating screen

|

2YK1545

|

15

|

1

|

| serial number | width(mm) | length(m) | angle(°) | power(kw) |

| 1# | 1200 | 27 | 16 | 30 |

| 2# | 1200 | 10+24 | 16 | 37 |

| 3/4#/ | 1200 | 24 | 16 | 22 |

| 5# | 800 | 20 | 16 | 11 |

| 6-9# | 650 (Article 4) | 20 | 16 | 7.5x4 |

| 10# | 650 | 15 | 16 | 7.5 |

| P1-P4# | 650 | 10 | 0 | 5.5 |

Note: This process is for reference only, all the parameters in the figure do not represent the actual parameters, the final result will be different according to different characteristics of stone.

Technical description

1. This process is designed according to the parameters provided by the customer. This flow chart is for reference only.

2. The actual construction should be adjusted according to the terrain.

3. The mud content of the material cannot exceed 10%, and the mud content will have an important impact on the output, equipment and process.

4. SANME can provide technological process plans and technical support according to the actual requirements of customers, and can also design non-standard supporting components according to the actual installation conditions of customers.